Welcome to the Hossfeld Bender Instruction Manual, your comprehensive guide to mastering the operation, setup, and maintenance of this versatile bending tool for professionals and hobbyists alike․

Overview of the Hossfeld Bender

The Hossfeld Bender is a versatile, universal bending machine designed for precision and durability․ It is suitable for professionals and hobbyists alike, offering the ability to bend pipes, tubes, and flat stock with ease․ The machine supports both manual and power modes, ensuring flexibility for various projects․ With its robust construction and interchangeable tooling, it delivers consistent results․ The Hossfeld Bender is ideal for fabricators, welders, and metalworkers, providing reliable performance for both simple and complex bending tasks․ Its compact design and user-friendly operation make it a valuable addition to any workshop․

Importance of the Instruction Manual

The instruction manual is essential for understanding the full capabilities of the Hossfeld Bender․ It provides detailed guidance on setup, operation, and maintenance, ensuring optimal performance․ By following the manual, users can unlock the machine’s potential, achieve precise bends, and extend its lifespan․ The manual also highlights safety protocols and troubleshooting tips, helping users avoid common mistakes․ Whether you’re a professional or a hobbyist, this guide is indispensable for mastering the Hossfeld Bender․ It serves as a comprehensive reference, enabling users to utilize the machine safely and effectively for years to come․

Key Features of the Hossfeld Bender

The Hossfeld Bender is a versatile and essential tool for precision bending, offering a wide range of capabilities․ It supports both manual and power modes, providing flexibility for different tasks․ The machine is designed to handle various materials, including tubes, pipes, and flat stock, with interchangeable dies for accurate bends․ Its robust construction ensures durability and consistent performance over time․ The Hossfeld Bender also features a user-friendly interface, making it accessible for both professionals and hobbyists․ With its ability to perform complex bends and its adaptable setup options, this tool is a reliable choice for achieving precise results in metalworking projects․

Installation and Setup

Installation is quick and straightforward with just four bolts, following simple, illustrated instructions․ The setup allows easy switching between power and manual modes for flexibility․

Hydraulic Cage Clamp Setup

The hydraulic cage clamp setup is essential for ensuring precise and secure bending operations․ Begin by aligning the clamp with the bending die, making sure it is properly seated and centered․ Tighten the clamp bolts gradually to avoid misalignment, ensuring even pressure distribution․ Refer to the Hossfeld Bender Tooling Brochure for specific torque specifications․ Next, connect the hydraulic lines to the power source, ensuring all connections are secure and free from leaks․ Check the hydraulic fluid level and top it off if necessary, using the recommended fluid type․ Finally, test the clamp by cycling it several times to ensure smooth operation․ Always follow the illustrated instructions provided in the manual for optimal setup and safety․

Tube Die Setup for Accurate Bends

Setting up the tube die correctly is crucial for achieving precise bends․ Begin by selecting the appropriate die for your tube size and desired bend angle․ Align the die with the bending chamber, ensuring it is securely fastened using the provided bolts․ Tighten the bolts evenly to maintain proper alignment․ For 180-degree bends, use the specialized 180 tube die, as highlighted in the Hossfeld Bender Tooling Brochure․ Once the die is in place, test the setup by performing a small bend to ensure accuracy․ Always refer to the Hydraulic Hardware Setup Guide for specific torque specifications and alignment tips․ Proper die setup ensures consistent, professional-grade bends every time․

Flat Stock Setup for Precision Bending

Setting up your Hossfeld Bender for flat stock requires careful preparation to ensure precise bends․ Begin by selecting the appropriate die for your specific flat stock thickness and desired bend angle․ Align the flat stock evenly within the bending chamber, ensuring it is flush against the die․ Secure the stock firmly using the provided clamps or hold-downs․ For sharp, 90-degree bends, consider using a flat-face radius block to maintain consistency․ Refer to the Hossfeld Bender Tooling Brochure for die selection guidance․ Always follow the Hydraulic Hardware Setup Guide for torque specifications and alignment tips to achieve professional-grade results․ Proper setup ensures accurate and repeatable bends for your projects․

Operating the Hossfeld Bender

Mastering the Hossfeld Bender involves understanding basic bending techniques, advancing to complex operations, and seamlessly switching between manual and power modes for optimal efficiency and precision․

Basic Bending Techniques

Begin by preparing the Hossfeld Bender according to the setup guide, ensuring all components are securely in place․ Start with manual mode for simplicity and safety․ Align the tube or flat stock with the designated bending die, ensuring proper positioning for accurate results․ Secure the material firmly using the hydraulic cage clamp to prevent slippage during operation․ Apply steady pressure to the bending lever, following the recommended angle guidelines in the manual․ For precise bends, use the flat-face radius block or Bulldozer Die as specified․ Always monitor the bending process to avoid over-flexing the material․ Practice with smaller projects to build familiarity and confidence in the machine’s capabilities․

Advanced Bending Operations

For complex projects, employ multi-radius bends by adjusting the bending die configuration․ Use the 180 Tube Die for creating precise 180-degree bends, ensuring material alignment with the die’s center mark․ When bending flat stock, utilize the Flat-Face Radius Block for consistent results․ In power mode, achieve faster and more precise bends by setting predefined angles․ Experiment with combining manual and power techniques for intricate shapes․ Always monitor material stress to avoid cracking or deformation․ For square bends, the Bulldozer Die is ideal․ Ensure all setups are secure and follow safety guidelines to maintain control during advanced operations․ Practice these techniques to master intricate bending tasks efficiently․

Switching Between Manual and Power Modes

Switching between manual and power modes on the Hossfeld Bender is straightforward, allowing flexibility for different tasks․ To transition from power to manual mode, remove the hydraulic drive and install the manual handle․ Ensure the handle is securely fastened to maintain control during operation․ For power mode, attach the hydraulic components and follow the setup guide for precise angle adjustments․ Always refer to the manual for torque specifications and proper connection procedures․ Practice switching modes to ensure smooth transitions and optimal performance․ This feature enhances versatility, making the Hossfeld Bender suitable for both small-scale and industrial applications․

Safety Guidelines and Precautions

Always wear protective gear, follow manual guidelines, and avoid dangerous shortcuts․ Handle hydraulic components safely and inspect equipment regularly to prevent hazards․ Follow emergency shutdown procedures․

General Safety Tips for Bender Operation

Ensure a safe working environment by following essential safety guidelines when operating the Hossfeld Bender․ Always wear protective gear, including gloves, safety glasses, and a face mask․ Keep loose clothing or jewelry tied back to avoid entanglement․ Maintain a clean and stable workspace to prevent accidents; Familiarize yourself with the machine’s components and functions before use․ Never operate the bender near flammable materials or in an area with poor ventilation․ Avoid overloading the machine, as this can lead to equipment damage or injury․ Ensure the bender is properly secured to a sturdy surface to maintain stability during operation․ Regularly inspect tools and accessories for wear and tear․ Follow all instructions in the manual to ensure safe and efficient bending operations․

Handling Hydraulic Components Safely

When working with the Hossfeld Bender’s hydraulic components, prioritize safety to avoid accidents and ensure proper function․ Always wear protective gloves and eyewear when handling hydraulic parts․ Avoid touching hot components, as they may cause burns․ Regularly inspect hydraulic lines for leaks or damage, and address issues promptly․ Use only manufacturer-recommended hydraulic fluids to prevent system contamination․ Keep the hydraulic cage clamp and surrounding area clean to maintain optimal performance․ Never attempt to modify or repair hydraulic components without proper training or manual guidance․ Follow the recommended pressure settings to prevent overloading the system․ Store hydraulic fluids in a well-ventilated area, away from open flames or sparks․

Emergency Shutdown Procedures

In case of an emergency, immediately press the emergency stop button located on the control panel to halt all operations․ Ensure all personnel are clear of moving parts before proceeding․ Disconnect the power supply to prevent accidental restarts․ If a hydraulic malfunction occurs, slowly release the hydraulic pressure according to the manual’s instructions to avoid sudden system failures․ Never attempt to remove or adjust components while the machine is under pressure․ If a leak is detected, contain the spill and ventilate the area․ Contact a certified technician for assistance with repairs; Always follow these procedures to ensure operator safety and prevent damage to the Hossfeld Bender․

Maintenance and Troubleshooting

Regular lubrication of moving parts and inspection of hydraulic components are essential for optimal performance․ Troubleshoot common issues like stuck dies or pressure drops promptly to avoid downtime․

Regular Maintenance Schedule

Regular maintenance is crucial for ensuring the longevity and optimal performance of your Hossfeld Bender․ Start by lubricating all moving parts every 50 hours of operation to prevent wear and tear․ Inspect the hydraulic system monthly, checking for fluid levels and signs of leakage․ Clean the bending dies and clamps regularly to maintain precision and avoid damage․ Replace worn-out dies and clamp pads as needed to ensure accurate bends․ Additionally, check the pressure gauge and adjust it according to the manufacturer’s specifications․ Schedule a thorough inspection every six months to identify and address potential issues before they escalate․

Common Issues and Solutions

Common issues with the Hossfeld Bender include hydraulic fluid leaks, misaligned dies, and inconsistent bending results․ For leaks, inspect the hydraulic system for worn seals and replace them as needed․ Misaligned dies can cause inaccurate bends; ensure proper setup and alignment before operation․ Inconsistent results may stem from worn dies or incorrect pressure settings․ Regularly check and replace dies, and refer to the pressure guidelines in the manual․ Additionally, if the bender stalls during operation, check for overloading or insufficient hydraulic power․ Addressing these issues promptly ensures optimal performance and extends the tool’s lifespan․ Always consult the manual for specific troubleshooting steps․

Wear and Tear Replacement Parts

Regularly inspecting and replacing wear and tear parts is essential for maintaining the Hossfeld Bender’s performance․ Common replacement parts include dies, hydraulic seals, and pivot pins․ Dies may wear out over time, leading to less precise bends․ Hydraulic seals can degrade, causing fluid leaks․ Pivot pins may show signs of wear, affecting the machine’s alignment․ Always use genuine Hossfeld replacement parts to ensure compatibility and longevity․ Refer to the parts list in the manual for specific items․ Replace worn components promptly to prevent further damage and maintain optimal bending accuracy․ Regular maintenance will extend the life of your Hossfeld Bender and ensure consistent results․

Additional Resources and References

For further guidance, refer to the Hossfeld Bender Tooling Brochure and Hydraulic Hardware Setup Guide․ Additional support is available in the Instruction Manual for Universal Pipe Tube Bender․

Hossfeld Bender Tooling Brochure

The Hossfeld Bender Tooling Brochure is an essential resource for understanding the full capabilities of your Hossfeld Bender․ This 8-page document provides detailed insights into the tooling options available for your machine, including tube dies, flat stock dies, and other accessories․ It also includes setup guides and troubleshooting tips to help you optimize your bending operations․ The brochure is available as a downloadable PDF, making it easy to access and reference whenever needed․ Whether you’re a professional or a hobbyist, this brochure ensures you’re equipped with the knowledge to get the most out of your Hossfeld Bender․ It’s a must-have companion for any user․

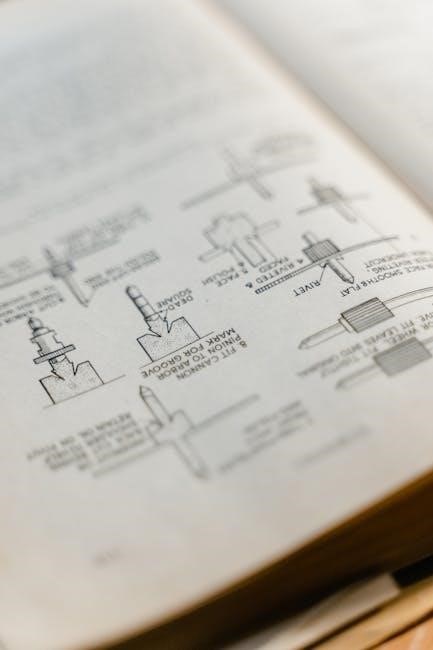

Hydraulic Hardware Setup Guide

The Hydraulic Hardware Setup Guide provides step-by-step instructions for configuring the hydraulic components of your Hossfeld Bender․ It covers the installation of the hydraulic cage clamp, ensuring proper alignment and secure mounting․ Detailed diagrams and illustrations are included to simplify the process․ The guide also explains how to connect hydraulic lines and test the system for leaks or malfunctions․ Additionally, it offers tips for maintaining optimal hydraulic performance and troubleshooting common issues․ This resource is indispensable for anyone setting up or servicing the hydraulic system of their Hossfeld Bender, ensuring safe and efficient operation․ Follow the guide carefully to achieve precise and reliable bending results․

Instruction Manual for Universal Pipe Tube Bender

The Instruction Manual for Universal Pipe Tube Bender provides detailed instructions for setting up and operating the Hossfeld Bender․ It includes step-by-step guides for installing hydraulic components, configuring tube dies, and performing precise bends․ The manual covers both manual and power modes, ensuring versatility for various projects․ Illustrated diagrams simplify complex processes, while troubleshooting sections address common challenges․ Safety precautions and maintenance tips are also emphasized to extend the tool’s lifespan․ Whether you’re bending pipes, tubes, or flat stock, this manual serves as an essential resource for achieving professional results․ It’s a must-have for anyone using the Hossfeld Bender․

Mastering the Hossfeld Bender requires careful study of this manual․ Follow safety guidelines, maintain equipment regularly, and explore advanced techniques for optimal performance and longevity of your tool․

Final Tips for Optimal Performance

To maximize the efficiency and lifespan of your Hossfeld Bender, ensure proper lubrication of moving parts and maintain a clean workspace․ Always use the correct die for your material type to achieve precise bends․ Regularly inspect hydraulic components for wear and tear․ Practice switching between manual and power modes to adapt to different projects․ Keep the machine well-maintained by following the recommended maintenance schedule․ Familiarize yourself with emergency shutdown procedures to handle unexpected situations safely․ By adhering to these guidelines, you’ll ensure consistent performance and extend the durability of your Hossfeld Bender․

Importance of Following the Manual

Adhering to the Hossfeld Bender Instruction Manual is crucial for safe and effective operation․ The manual provides detailed guidelines for setup, operation, and maintenance, ensuring optimal performance and longevity of the machine․ By following the instructions, users can avoid costly errors, prevent damage to the bender, and guarantee precise bends․ The manual also outlines essential safety precautions, reducing the risk of accidents․ Proper usage, as described, helps maintain warranty validity and ensures compliance with industry standards․ Regular maintenance schedules and troubleshooting tips in the manual further enhance efficiency and reliability․ Consistently referring to the manual ensures consistent results and extends the machine’s service life․

Continuous Learning and Improvement

Continuous learning and improvement are essential for maximizing the potential of your Hossfeld Bender․ Regularly reviewing the instruction manual ensures familiarity with new features and optimal operating techniques․ Staying updated with manufacturer resources, such as tooling brochures and setup guides, provides insights into advanced bending methods․ Engaging in hands-on practice and experimenting with different materials and dies enhances proficiency․ Additionally, participating in workshops or online forums can offer valuable tips from experienced users․ By embracing a mindset of continuous improvement, operators can refine their skills, adapt to new technologies, and achieve precision in every bend․ This commitment to learning fosters long-term mastery and confidence in using the Hossfeld Bender․